We use cookies to provide great user experience. By continuing on this site you accept use of the cookies.

We use cookies to provide great user experience. By continuing on this site you accept use of the cookies.

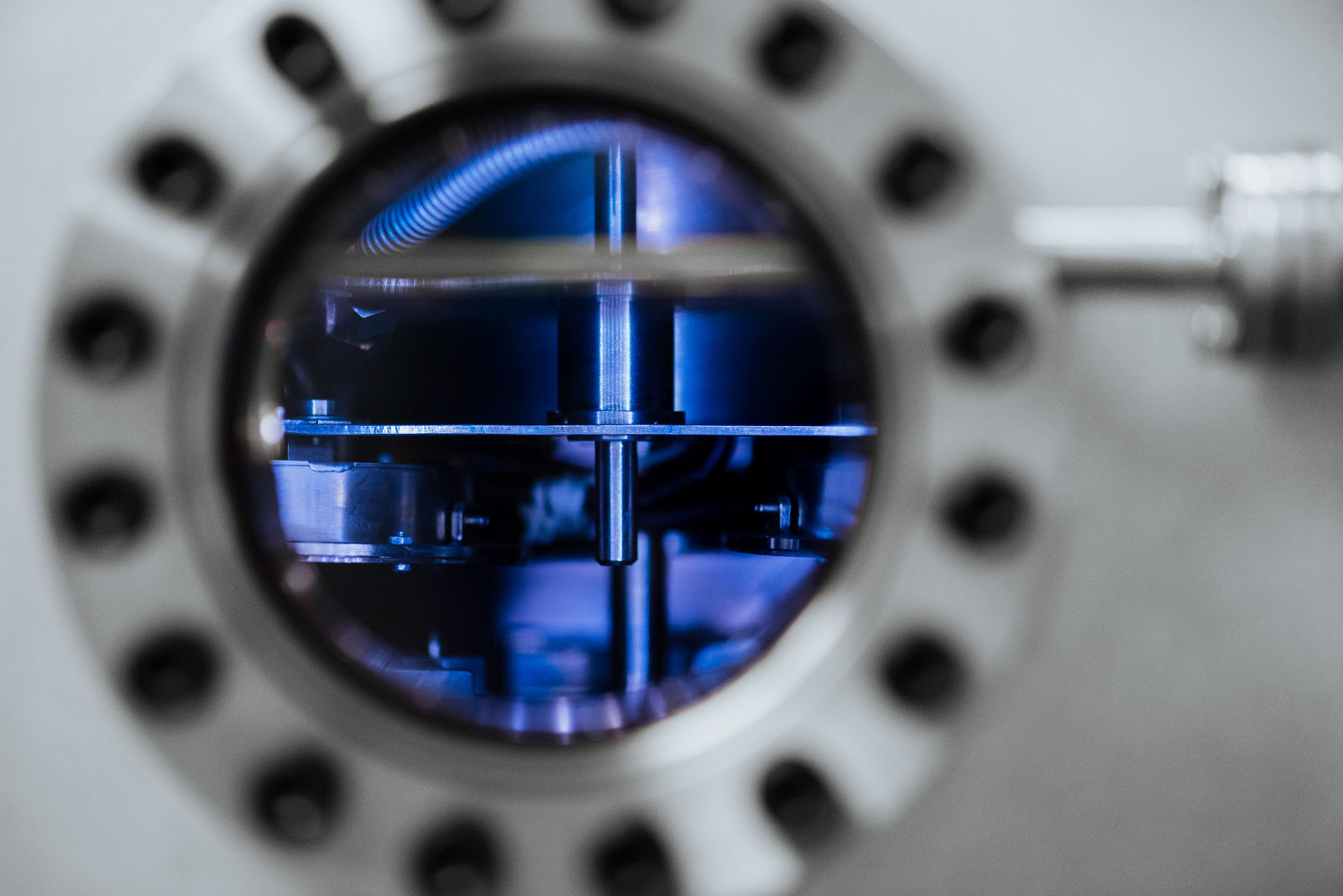

Our custom-made multifunctional cluster tool can be used for developing thin films and coatings of both inorganic and organic materials. All processes take place in our cleanrooms, with an ISO classification of 7-8.

We work with the major thin- film technologies: magnetron sputtering, low-temperature evaporations, high-temperature evaporation and e-beam evaporation.

We can make sample manufacturing aimed at product prototyping to form market evaluation of out-of-box technologies.

We also work with wet casting of materials which is irreplaceable to develop, for example, thin films used in OLEDs, organic photovoltaics or organic transistors.

For materials that can be harmeddamaged by oxygen, a wet chemical coating can be done applied in an inert atmosphere (Ar). For that reason, we use a spin coater placed in the glovebox.

For your bigger visions, we can offer scaling your technologies to industrial scale with our partners Sidrabe – well known supplier of vacuum coating systems and processes and EuroLCDs – innovative LCD technology developer. We have strong collaboration also with smart glass developer – Groglass.

We can work together from early-stage material development, through the prototype stage and up-scaling, to industrial proof of newly-developed thin-film technology.